Homeowners in Essex choose flat roofs for pragmatic reasons. They make loft conversions workable, hold solar panels without fuss, and keep extensions neat against older brickwork. Their clean lines suit contemporary architecture yet don’t jar with Victorian terraces or post-war semis. If you manage them well, flat roofs can run for decades without drama. If you neglect them, they tend to tell you quickly, sometimes over the dining table.

Skylights and rooflights have shifted from a nice-to-have to a core feature on many projects across the county. A dark rear extension in Southend feels different once a couple of carefully placed panes pull sunlight from the sky. A tiled kitchen in Billericay warms at noon without a single lamp switched on. With natural light now high on wish lists, add-ons like domes, walk-on glass, lanterns, sun tunnels, and green roof build-ups serve real, everyday needs. They also force you to think carefully about the roofing membrane, drainage, insulation, and maintenance, because glass and penetrations raise the stakes.

What follows blends onsite lessons from flat roofing in Essex with a grounded look at options that work, options that often disappoint, and the practical steps to keep the roof tight for years.

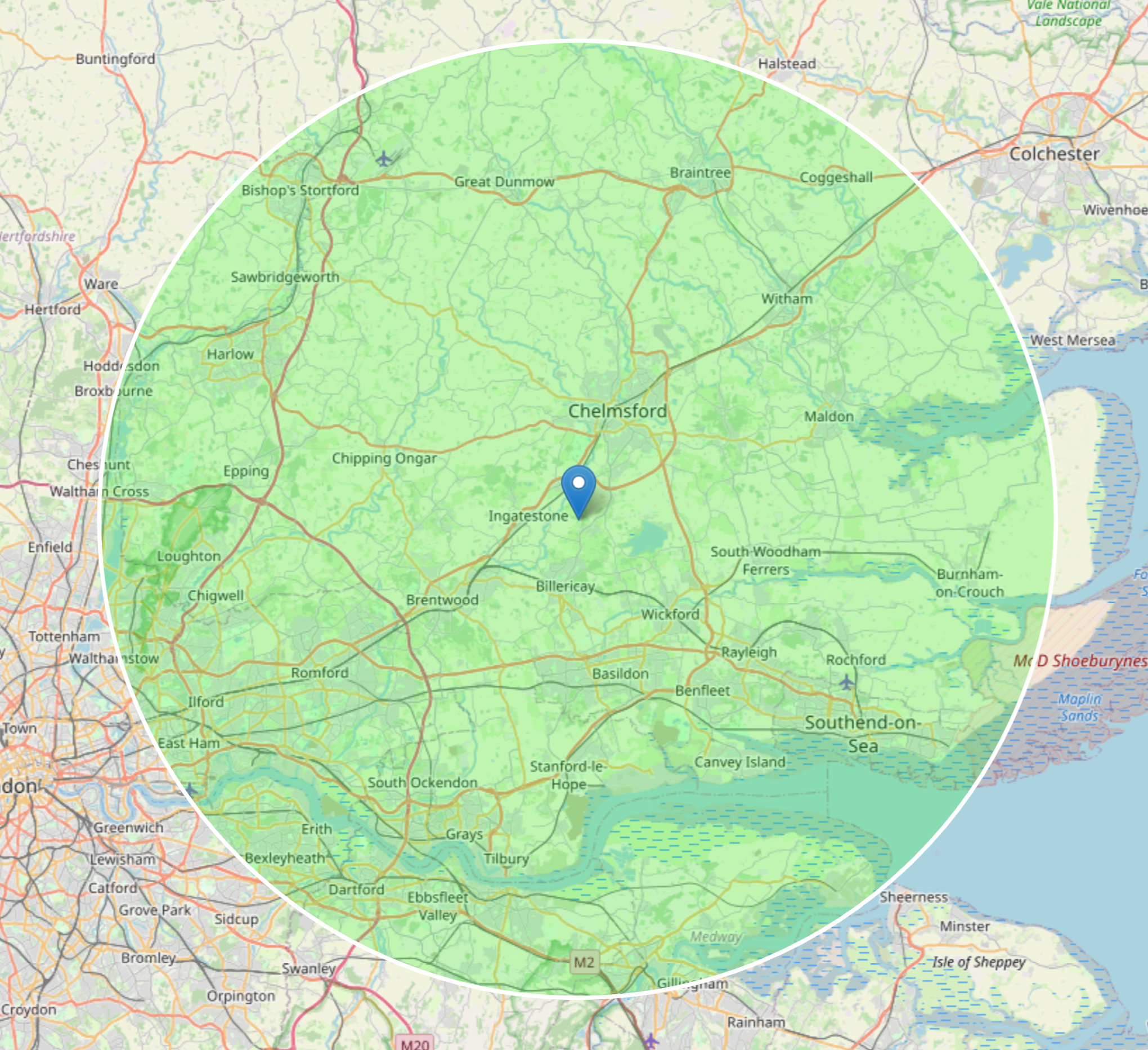

The Essex context: weather, planning, and housing stock

Essex weather doesn’t sound dramatic until you live with a flat roof. You get long, damp spells and wind-driven rain off the estuary, plus sudden heat in summer that can push surface temperatures on a dark membrane to 60–70°C. Roofing materials expand, contract, and creep. If detailing isn’t right around a rooflight kerb, sealants shear and tiny capillary paths pull water in. The county’s mix of coastal air, urban dust, and tree cover loads gutters faster than many realize.

Housing stock matters too. In Chelmsford or Colchester, rear and side extensions often sit under a parapet or trim with limited fall. Many roofs are inherited alongside the house: layered felt on old chipboard decks, cut-to-falls insulation that has flattened, and two or three generations of repairs baked in. When someone asks about a new lantern, you need to talk first about substrates, falls, and load-bearing. Setting glass over a spongy deck is a false economy.

Planning is usually straightforward for low-profile rooflights, as most fall within permitted development. Lanterns and taller domes sometimes require a nod to visual impact, especially in conservation areas. Local planners generally want assurances on height and edge visibility from the street. Get these conversations done early; changing an opening size once steel is in place turns into a compromise no one likes.

Roofing membranes that play nicely with glass

The fabric of the roof sets your margin for error. You can fit a beautiful skylight onto a poor membrane and still end up living with a drip. For flat roofing Essex homeowners typically choose between high-performance felt (SBS-modified bitumen), EPDM rubber, single-ply PVC or TPO, GRP (fibreglass), and liquid-applied systems like PU or PMMA resins. All can work with rooflights if detailed properly, but each behaves differently at the kerb and under heat.

SBS felt remains a staple across Essex because it’s forgiving and robust. Torch-on or self-adhesive systems wrap neatly around timber kerbs and take a clean lead or metal flashing at abutments. I see plenty of felt roofs still dry after 20 years in Rayleigh and Hockley, despite heavy leaf fall. The trick is strict discipline at laps and making sure the upper pour-and-roll relics are stripped back to sound substrate, not used as a base.

EPDM suits large, simple roofs with few penetrations. It excels at being one piece, which removes many joints. The potential pitfall is how you turn it up and over kerbs and keep adhesion around tight internal corners. Preformed corner pieces help, and mechanical trims at edges save a lot of grief. I’ve had to revisit DIY EPDM jobs where sealant bridged gaps instead of proper primed tape seams; Essex wind tugged those seams loose in a couple of winters.

Single-ply PVC or TPO gives a clean, white or light-grey surface that keeps summer temperatures down. Welded seams, done right, are watertight and tidy. You need an installer comfortable with hot-air welding, not just a general builder. It also wants the right insulation beneath to avoid plasticizer migration or chemical incompatibility. Around rooflight kerbs, use factory-formed collars if available, or weldable upstand membranes.

GRP worked into OSB3 makes a solid platform for small and medium roofs with lots of edges. It forms crisp corners at rooflight kerbs and copes with complex shapes. The resin must be applied within correct temperature and humidity windows; push it on a cold, damp day and you lock in pinholes. I see the best GRP results on smaller roofs where installers control curing and avoid rush jobs.

Liquid-applied resins shine for refurbishment with many penetrations. On older roofs in Brentwood, where a past extension has six service pipes, two vent covers, and a rooflight, a liquid membrane can wrap every odd angle. The substrate prep dictates success: clean, dry, primed, with cracks and transitions reinforced using fleece. The same applies at rooflight upstands; resin needs a bondable surface and proper termination.

For any system, I aim for 150 mm minimum upstand height around rooflights above finished roof level. In heavy rain, low upstands invite splashback and wind-driven ponding. Building regs point to 150 mm for good reason. Yes, in cramped situations around parapets you might negotiate down to 75–100 mm with careful detailing, but you inherit risk.

Choosing the right platform for the light

People often start by pointing to a product they like on Instagram: a flush walk-on pane or a steel-framed lantern with Georgian bars. The better start is to look at how the room works and how the roof is built. If the room wants soft, even illumination, multiple smaller rooflights spread across the space beat one large lantern at the centre. If the room wants a statement over an island or dining table, a lantern earns its keep.

Lanterns boost height inside and drip warm daylight down. They also add wind load and more joints. On an exposed site near the coast, a low-profile pyramid with a continuous ridge might be quieter in a storm than a tall, multi-bar setup. Flat glass rooflights with a slight pitch look minimal, shed water well, and keep lines clean. Domes are practical, cost-effective, and surprisingly efficient at daylighting, though not everyone loves their look.

Walk-on glass works over basements and terraces. It is heavy, needs structural support designed by someone with calculations, not guesswork, and demands scrupulous waterproofing at the perimeter. If you plan a walk-on pane above a kitchen in Leigh-on-Sea, consider slip resistance on top, condensation control below, and the reality that footprints and leaves show.

Ventilation matters more than people expect. Kitchens and bathrooms love opening panes. Electric actuators with rain sensors solve the classic British summer shower issue. Manual winding mechanisms are fine when the shaft length is reasonable and the operator won’t be a child trying to swing off it. Chain drives hide well and handle most small rooflight sashes. For larger panes, a linear actuator earns its keep.

Thermal performance is non-negotiable. Aim for a centre pane U-value around 1.0 W/m²K or better, with a whole unit value that acknowledges frames and spacers. Double or triple glazing with warm-edge spacers and argon becomes standard rather than luxury. Think about solar gain too. A south- or west-facing lantern can turn a room into a greenhouse at 4 p.m. in July. Solar control coatings trim g-value and keep comfort. Use blinds if you value late-afternoon TV without glare.

Detailing that keeps water out

Rooflights invite water because they interrupt the simplest path to the outlet. The difference between a dry ceiling and stained plaster usually lives in two places: the upstand and the drainage. A good upstand is square, true, and bonded with the roof membrane in a continuous, clean run. Where the membrane turns onto the vertical face, you reinforce internal corners with preformed patches or neatly cut pieces, not blobs of mastic. The top termination under a capping or clamped frame is where many DIY jobs fail; if the frame doesn’t compress a gasket against the membrane, add a compatible termination bar and sealant bead.

Drainage is dull until the first storm. A rooflight placed in a ponding area suffers. Even 5–10 mm of standing water laps against seals and accelerates grime build-up that chews UV-protective coatings. Proper falls matter. British practice likes 1:40 design fall to achieve 1:80 finished fall. On refurbishments, I sometimes use tapered insulation to reinvent falls without rebuilding the whole deck. That adds cost but saves years of minor frustration.

A common request across flat roof repair Essex calls is quick fixes for perished sealants. Sealant should be a belt, never the only pair of braces. If you rely on beads to bridge gaps wider than a few millimetres, they fail with movement. Where possible, rework the upstand to accept a proper clamped frame or mechanical termination, then re-seat the glazing.

Condensation, thermal bridges, and comfort

Glass invites condensation if the install ignores physics. Warm, moist air from a shower or hob rises, touches the colder glass, and steams it up. If that condensation rolls and finds unprotected timber, you inherit a hidden rot problem. Counter this with three measures: reduce moisture at source, ventilate intelligently, and provide warm edges and thermally broken frames. Trickle vents on a rooflight help but are not a substitute for an extractor that actually gets used. In airtight homes, automated ventilation tied to humidity sensors pays for itself in paint saved.

Thermal bridges around the rooflight kerb transmit cold into the interior. A kerb constructed from insulated timber or proprietary insulated upstands performs better than raw timber. I like to wrap kerbs with insulation where the membrane allows and ensure internal plasterboard doesn’t run tight to the cold exterior face. Use airtight tapes around the internal perimeter to stop warm, moist air from pumping into the void.

Noise is another comfort factor. Rain drum on some thin domes can be intrusive in a bedroom. Laminated glass reduces external noise and improves safety. Triple glazing helps with both acoustics and energy, though it adds weight, which the kerb and fixings must welcome.

Green roofs, solar panels, and the rhythm of maintenance

Essex has embraced green roofs on garden rooms and M.W Beal & Son Roofing Contractors essex roofing M.W BEAL & SON Roofing Contractors - Roofers in Essex extensions for good reason. They soften views from upstairs windows and help manage stormwater. An extensive green roof adds 60–150 kg/m² when saturated. You need confirmation that joists, deck, and supporting walls can carry that. The membrane must resist root penetration; many single-ply and liquid-applied systems offer certified root-resistant versions. Introduce inspection chambers at outlets so you can clear roots and moss without ripping the planting.

Solar panels want structure and waterproofing to be on speaking terms. I prefer ballasted or low-penetration mounting on flat roofs, using wind-calculated weights. Every penetration is a future call-out unless absolutely necessary. Panels cast shade, which can cool parts of the roof while other parts bake; membranes that tolerate thermal cycling gracefully fare better. Plan panel layout around rooflights to avoid unwanted shadows or cleaning access issues.

Maintenance is where most roofs either quietly excel or quietly fail. A flat roof with rooflights wants a simple rhythm: visual checks after heavy weather, seasonal gutter clears, and an annual gentle wash of glazing with non-abrasive cleaner. If trees overhang, double that frequency. Neglect lets algae creep into seals and fine grit abrade coatings. For liquid-applied and single-ply roofs, avoid solvent-based cleaners that could soften the membrane. Keep a log with dates and photos; it helps if you ever need a warranty claim.

Here is a short, focused checklist that keeps owners on track without turning it into a chore:

- Clear leaves and debris from outlets and gutters at least twice a year, more often under trees. Inspect rooflight seals, gaskets, and fixings annually, tightening as needed and replacing perished rubber. Look for ponding areas after rain; if water remains after 48 hours, investigate falls and outlet capacity. Wash glass with a soft brush and mild detergent; avoid pressure washers close to seals. Photograph the roof and rooflights each spring to spot slow changes like seal shrinkage or membrane scuffing.

Budgeting realistically and avoiding common traps

Costs in Essex vary because access and substrate condition swing the labour. A straightforward 20 m² EPDM layover with one fixed rooflight might sit in the £2,500–£4,500 range for competent installers, rising with better glass and insulated kerbs. A full strip, new warm roof build-up, box gutter modification, and two opening rooflights could double or triple that. Lanterns add more both in product and labour, especially if the opening needs trimming with steels.

A little planning saves a lot of money. Combine roofing and rooflight work. Ordering a lantern after the membrane is down means cutting into new work. Pre-order lead times matter. Standard sizes turn up quickly; custom panes or walk-on units can take six to ten weeks. If the house is occupied during works, plan for temporary weathering. Leaving an open hole overnight courts disaster in an Essex squall. Good crews carry shrink-wrap, tarps, and temporary ply lids sized before they cut.

Several traps repeat across flat roof repair Essex call-outs:

- Over-reliance on silicone. It has a place as a finishing touch, not as structure. If you can peel it off in a strip and see daylight, the job needs redoing. Inadequate kerb height. Once a roofline is finished with slabs or decking, the original 100 mm upstand can shrink visually to 40–50 mm. That margin disappears in heavy rain. Plan kerb height with finish levels in mind. Unvented voids. Installing a rooflight into a cold roof without addressing ventilation invites interstitial condensation. Warm roof conversions fix more than one problem: energy, condensation, and deck longevity. Mismatched materials. Bitumen smeared onto a PVC membrane looks sealed for a month, then wages war. Use compatible adhesives, tapes, and primers as per the system data sheets.

Warm roofs, cold roofs, and why build-up matters

Many older Essex extensions are cold roofs: insulation between joists, ventilated void, deck on top. They can work if ventilation is perfect, but perfect rarely happens once kitchen fitters and electricians punch extra holes for services. Warm roofs place rigid insulation above the deck, membrane above the insulation, and keep the structure warm. This setup is kinder to timber and reduces condensation risk.

When adding rooflights, warm roofs simplify detailing. You continue insulation up to the kerb, maintain continuity around the perimeter, and keep the internal surfaces closer to room temperature. The kerb can be insulated on its exterior face to reduce the cold line. Always match insulation type to the membrane. PIR boards are common, but you need a proper vapour control layer beneath and a mechanically fixed or bonded finish per manufacturer guidance.

In refurbishments, a hybrid approach sometimes bridges constraints. If headroom is tight and you can’t add much thickness above, you might improve between-joist insulation while adding a thinner overlay with tapered falls. It’s not textbook, but with a smart vapour control strategy and careful air-sealing, it beats doing nothing.

Natural light strategy: not just how much, but where and when

A single, large rooflight can throw dramatic beams and strong shadows. That suits a dining table where you want a highlight. In a home office, the same shaft of light causes glare on screens. I often recommend several smaller units aligned with the functions below. Two panes over a kitchen island, one fixed and one opening near the hob, strike a balance between light and ventilation. A small rooflight placed toward the back of a deep plan reduces the cave effect better than a bigger pane near the bifolds.

Anecdotally, I recall a ground-floor flat in Witham where we swapped one 1,000 × 2,000 mm pane for two 800 × 1,000 mm units spaced apart. Light levels felt higher, not lower, because it spread evenly and reduced the sharp contrast that strained eyes. In winter, lower sun angles still reached deep enough, while summer glare was easier to manage with blinds.

Orientation changes the brief. North-facing rooflights give soft, consistent light; south and west cause heat spikes. East brings cheerful morning light to breakfast nooks. If energy is a priority, consider a selective coating that cuts infrared without turning the glass into a mirror.

Safety, access, and how people will live with the roof

Access shouldn’t be an afterthought. If you need to service an actuator or clear leaves, plan a safe route. Edge protection during works is mandatory; after handover, consider permanent tie-off points on larger roofs. Walk-on panes need anti-slip finishes that stay grippy in winter algae. Not every anti-slip film is pleasant under bare feet on a terrace, so test samples if you expect frequent use.

Security on low roofs matters. Some ground-floor extensions back onto alleys. Specify laminated inner panes and lockable openers. Many rooflight systems have security-tested ratings; they are worth the small premium. Vent positions should prevent curious hands from reaching in.

Fire safety factors have grown more stringent. Use materials with appropriate reaction-to-fire ratings, and ensure rooflights in certain zones meet fire performance where required by Building Regulations. Bedrooms off inner rooms might need rooflights that can act as means of escape, with minimum openable sizes. In practice, pivoting or top-hung openers can meet these, but always check the clear opening after frames and stays.

Working with builders and warranties that mean something

The best installations happen when the roofer and the builder talk early. The builder frames the opening, trims joists, and provides a square, level kerb at the right height. The roofer integrates the membrane and manages falls to outlets. If those roles blur without coordination, you get proud kerbs that pond water or wavy openings that flex frames.

Choose products and systems with traceable warranties. A 20-year membrane warranty paired with a 10-year rooflight warranty means little if installation voids both. Many manufacturers offer project-specific guidance and approved installers. Use that. Keep receipts, serial numbers, and photos of each stage: deck condition, vapour control, insulation, membrane, and rooflight fixing. If you ever need to prove the job was done to spec, that folder saves headaches.

I’ve revisited jobs ten years later where the only work needed was a new gasket on an opener. The owners had kept the installation notes and service dates. That habit is the difference between replacing a £30 rubber and an entire frame because no one could identify the model.

When repair makes sense and when replacement pays

For flat roof repair Essex requests, the first question is stability of the substrate. If the deck is sound and the leaks trace to aged seals around a rooflight or minor membrane scuffs, targeted repairs work. Swap gaskets, re-seat the clamping frame with new compressible tapes, add a correctly sized termination bar, and reinforce the membrane with compatible patches. Budget hundreds, not thousands.

When the deck feels soft underfoot, when you smell mustiness in the void, or when you see multiple repair layers curling, replacement wins. It’s tempting to piecemeal repairs each spring, but costs add up and risk remains. A proper strip, warm roof build-up, corrected falls, and new rooflights deliver lower bills over five to fifteen years. Consider energy savings too; a badly insulated cold roof leaks heat every winter day.

On heritage properties with sensitive sightlines, repair might be the only route permitted. In those cases, you can still upgrade discreetly: slimmer-profile fixed rooflights, internal secondary glazing to improve U-values, and noninvasive membranes that slip under existing lead or stone.

A practical path from idea to finished roof

If you are planning a rooflight or lantern on a flat roof in Essex, a sensible sequence avoids common pain:

- Assess existing structure and falls. Lift a small test area if needed to inspect deck and joists. Decide light strategy by use, orientation, and ventilation needs. Sketch placements in plan and elevation. Choose membrane system compatible with the structure and the number of penetrations. Confirm upstand heights. Order products with lead times in mind. Lock sizes before framing, not after. Coordinate builder and roofer on kerb construction, insulation continuity, and temporary weathering. Photograph stages and keep documents, including data sheets for adhesives and tapes actually used.

The final roof shouldn’t draw attention to itself on a wet November evening. It should keep quiet, hold its line, shed water, and let daylight do the talking in the rooms below. When the first frost hits and the sun still finds your countertop through a clear, dry pane, you’ll know the choices were sound.

Flat roofing Essex projects thrive on that blend of design and discipline. Pick materials that suit the job, detail rooflights as part of the roof rather than ornaments stuck on top, and keep a modest maintenance routine. Whether your goals are a brighter kitchen in Romford, a calm studio in Epping, or a robust flat roof repair Essex homeowners can trust, the principles stay the same: respect water, plan for movement, and make every junction earn its keep.